We manufacture high-quality, precision and cost-efficient stamped parts for the automotive, construction, electrical and electronics industries as well as for companies in the medical, sensor technology, communications and mobile communications technology sectors as well as numerous other industries that demand high-quality products to be successful.

Components and assemblies for electric mobility and battery technology as well as state-of-the-art press-fit zones complement our portfolio. Using state-of-the-art production systems, your specifications are met to the letter. A number of competencies for special-purpose applications complement our portfolio. See for yourself.

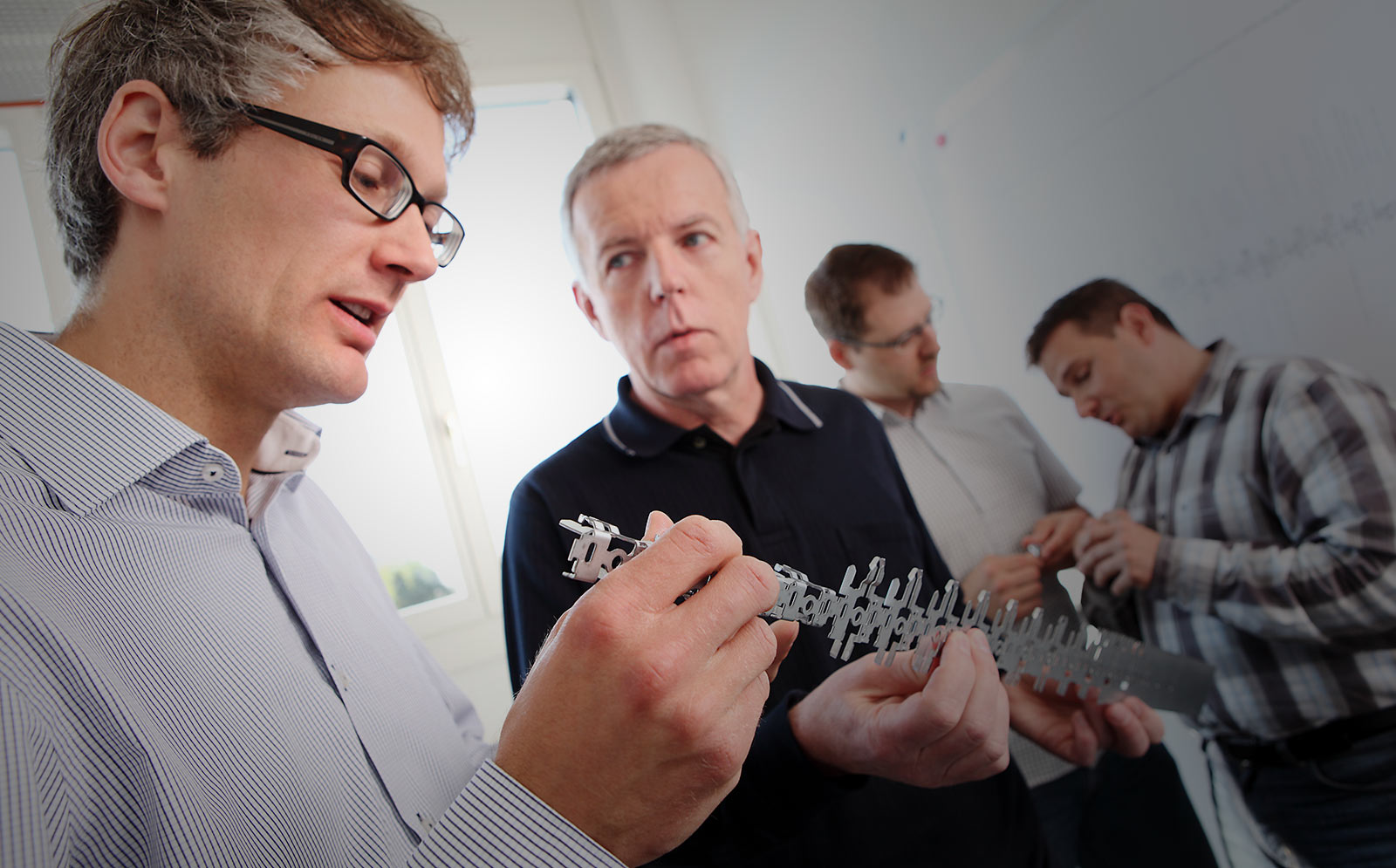

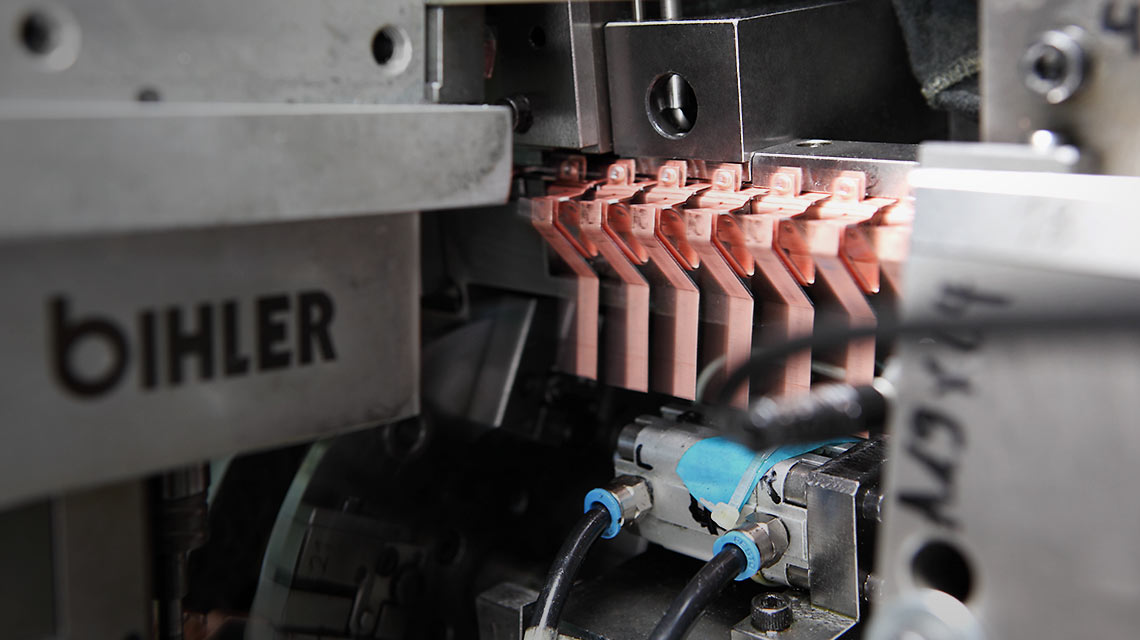

With us, you always have the specialists at your side. Whether in producing sophisticated and complex stamped and bent wire parts as well as in all manner of follow-up operations. Take advantage of our technology expertise in making long-lasting products with reliability that's guaranteed. The latest technical systems from BIHLER, conventional or with servo technology such as the servo-controlled GRM-NC stamping and forming machine, in combination with Lean-Tools, a lean, standardised tool concept, provide capabilities for producing volumes ranging from small-scale runs to several hundred million parts a year.

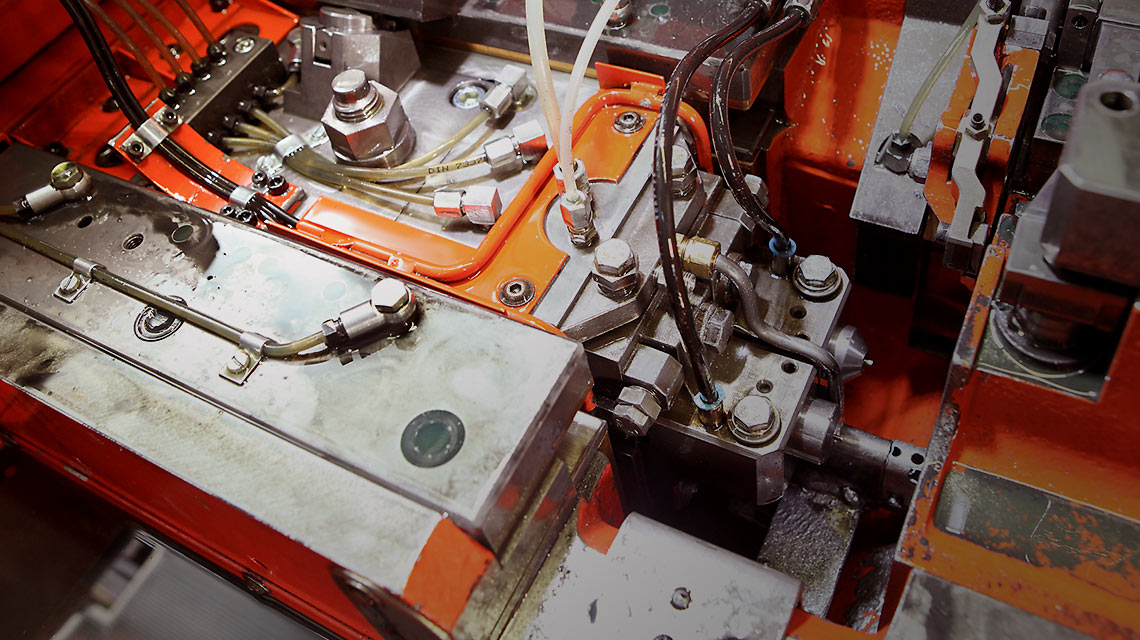

With this efficient production technology, we produce a formed part from a wire segment in two to seven forming stages. Cold and warm forming processes are marked by:

- material savings

- high-volume output

- special-purpose forming capabilities

- cost-effective alternative to turned parts

- high mechanical strength of parts

- high constancy of the parts geometry

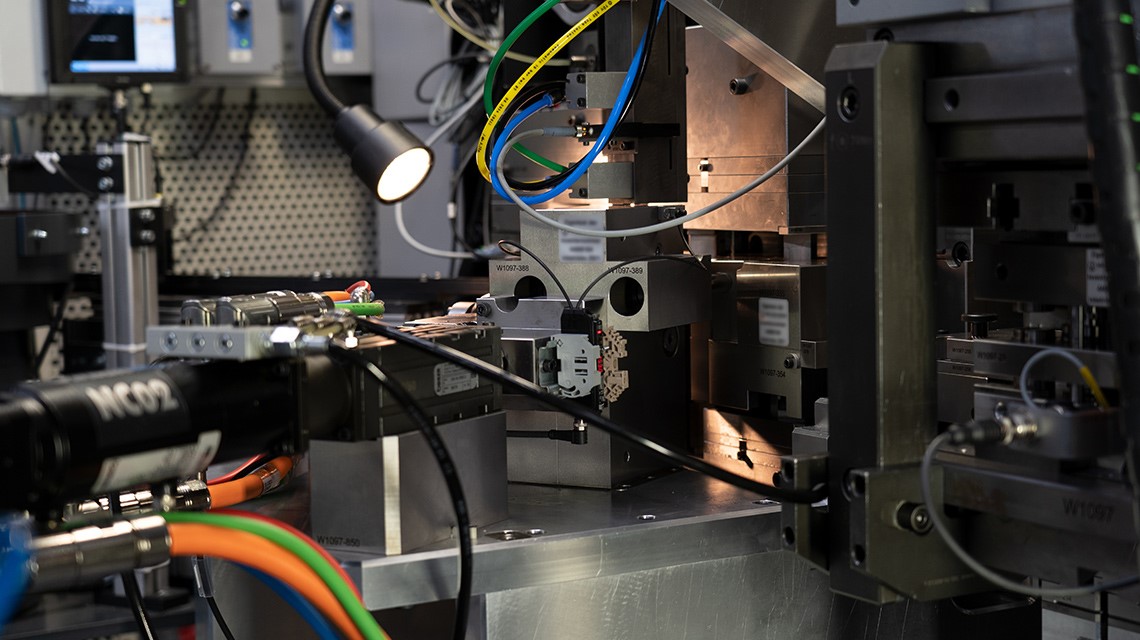

Assembling components is one of our core competences. No matter whether an assembly consists of several stamped parts or is a combination of stamped part, turned part, cold-headed part, milled part, contact rivet, cable, wire, plastic component or standard part, we are the experts in fully automated component assembly with the aim of supplying our customers with a ready-to-install assembly or a complex system on a just-in-time basis for a variety of end uses. In many cases, this is where we only need a single-stage production cycle in combination with the stamping process.

Overmoulding of stamped parts, stamped grids or stamped strip for the production of high-quality hybrid components complement the range of activities covered. As early as the development phase, we optimise the tolerance ranges of stamped parts to the necessary plastic-compatible minimum, thereby maximising quality far beyond the level required and demanded by the customer.

In combination with BIZON® press-fit contacts, hybrid housings are produced that permit trouble-free assembly of the printed circuit board in the downstream, follow-on process.

To assemble small-volume batches, we set store by tried and proven manual assembly or semi-automatic processes as well as the experience and dexterity of our staff.

Your career at Fischer Reinach AG

High-performance and state-of-the-art: Fischer Reinach AG is one of the leading companies in the supply industry. As a group company of a family-owned industrial holding company, we are proud of the continuous growth of our company. The group of companies currently has 350 employees based in Switzerland and Germany who are fully committed to this. When will you join the team?

Go to Careers at Fischer Reinach

Training and pacements

Cross-border exchange possible